Multilayer Pcb Manufacturing Process Steps

Making a double sided pcb.

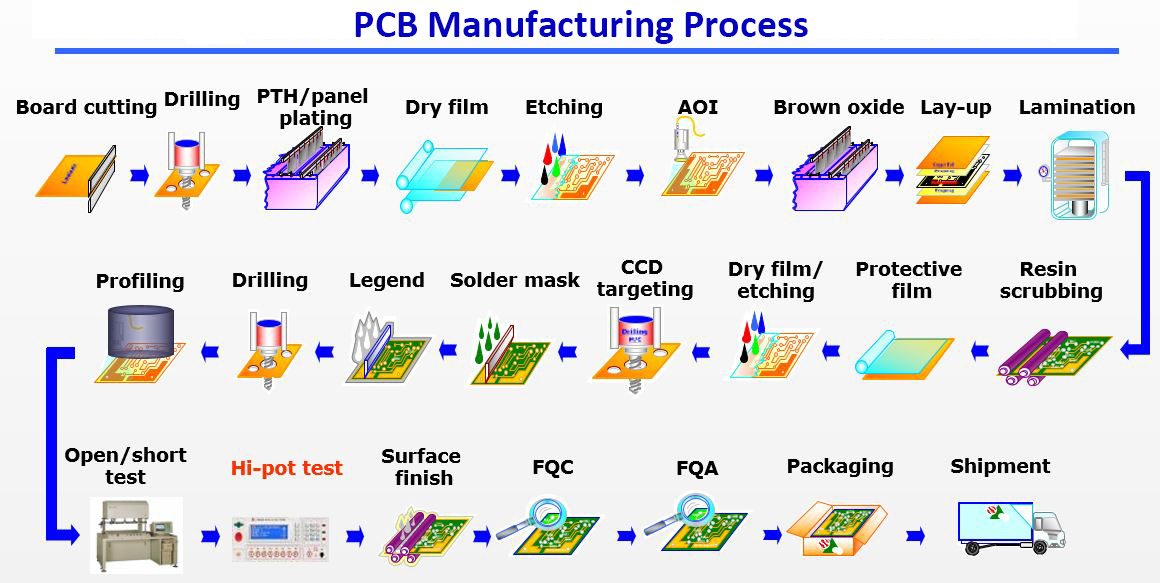

Multilayer pcb manufacturing process steps. The last etching step 12. A new soldermask for eurocircuits. Because it is made by electronic printing it is called printed circuit board. Jlcpcb is a pcb manufacturing company with a full production cycle.

Electrical reliability testing step. From raw materials to finished products everything is done right under the roof. Finishing pcb and silkscreening step 15. Basic pcb manufacturing process step by step.

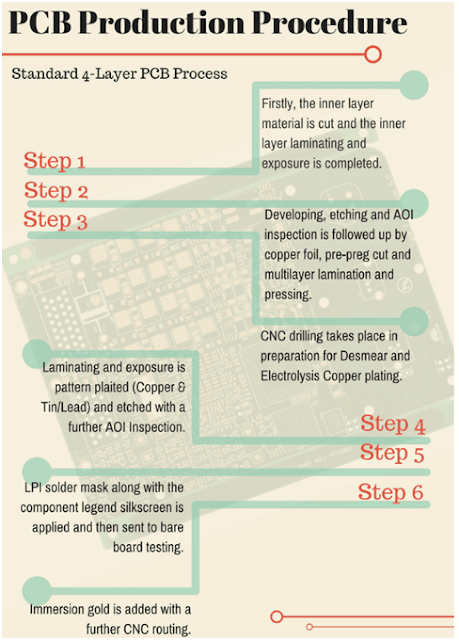

Electronic products in the production process there will be a printed circuit board production process. Laminating the pcb layers step 7. Direct imaging boosting the quality of pcb s. Selecting the right surface finish.

Getting rid of the unneeded copper step 5. This is normally a three step process. The third and final step is to chemically remove the tin deposit leaving the circuitry. Designing the pcb step 2.

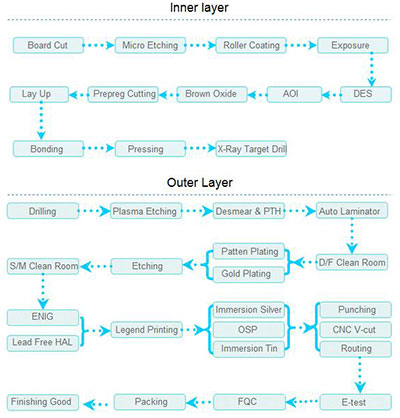

Printing the copper for the interior layers step 4. Printing the pcb design step 3. The first step is to remove the blue dry film. Which means they start from a and finishes with z of pcb manufacturing process.

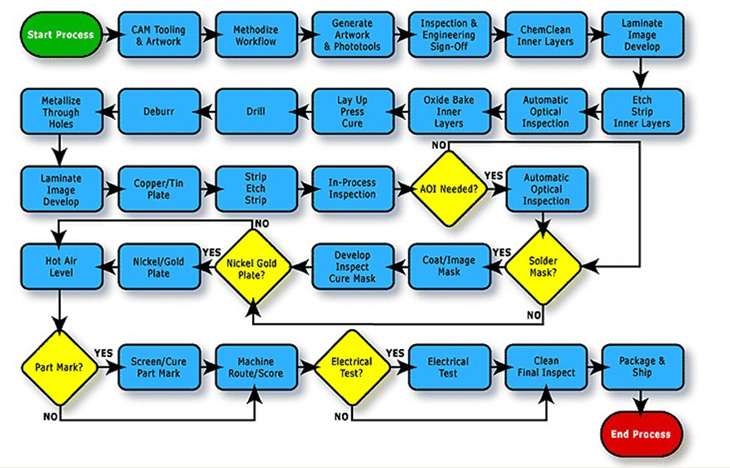

Once we receive gerber data from the customer we send to cad department we check customer data meets our manufacturing requirements. Pcb or printed circuit board is an important electronic part and the support body of electronic components. Soldermask for via holes pads. These checks are mostly done automatically.

The process starts with designing layout of the pcb using any pcb designing software cad tool proteus eagle orcad. This step in the manufacturing process begins by using a laminator machine to coat the outer layers of the bare copper panel with dry film a photo imageable material also known as photoresist or dry film resist. Soldermask on via holes with nickel gold finish. The first step is to remove the blue dry film.

The pcb goodness emerges victorious from within its shell of. Industrial pcb manufacturing steps. Inspection and layer alignment step 6. Imaging and plating the outer layer step 11.

The third and final step is to chemically remove the tin deposit leaving the circuitry. It s a simple matter of removing the restraining pins and discarding the top pressure plate. Making a pcb step by step. The second step is to etch away the exposed unwanted copper whilst the tin deposit acts an etch resist protecting the copper we need.

Following are the steps involved in multilayer pcb manufacturing process. Pcb plating step 9 10. With all the layers molded together in a super sandwich of pcb glory the technician simply unpacks the multi layer pcb product. This is normally a three step process.

Via holes in pads. The second step is to etch away the exposed unwanted copper whilst the tin deposit acts an etch resist protecting the copper we need. Pcb manufacturing process steps step 1. Drilling step 8.

Next step is to make the inner layer core. This process is like the one used to image the inner layers of a multi layer pcb.